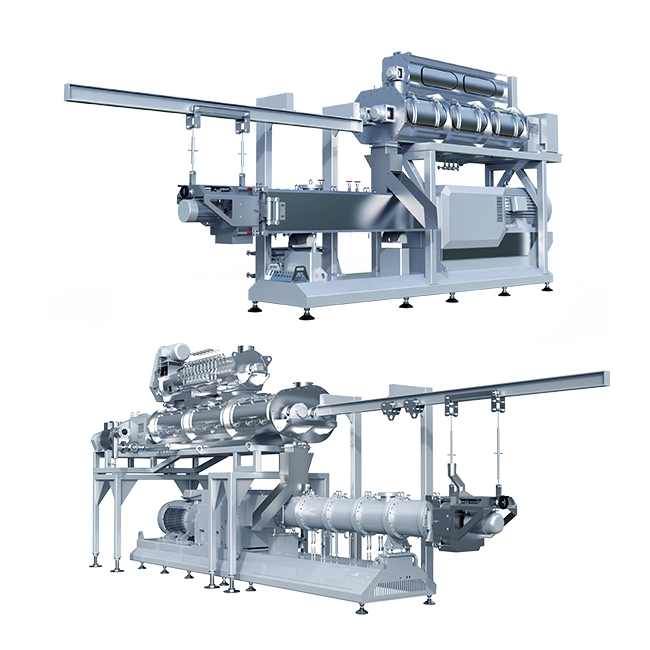

In the aquaculture industry, feed quality directly impacts growth, health, and sustainability. That’s why producers turn to FAMSUN—a trusted leader in feed processing technology. The Twin-Screw Aqua Extruder, part of FAMSUN’s H series, is a highly adaptable food extruder designed to handle a wide variety of aquafeed formulations with precision and efficiency.

Adaptable to All Feed Types

The FAMSUN Twin-Screw Aqua Extruder is engineered for versatility. It can produce floating, sinking, slow-sinking, and micro aquafeeds—ensuring that different species and growth stages are met with the ideal nutrition profile. Its flexibility allows feed producers to switch formulations easily without compromising product consistency.

Consistent Quality Across Formulas

Whether processing high-protein fish feeds or micro diets for larvae, FAMSUN’s advanced food extruder ensures uniformity in size, shape, and density. This precision enhances digestibility and minimizes waste, leading to better feed conversion ratios and healthier aquatic animals.

Efficient Production, Lower Costs

With a robust twin-screw design, the FAMSUN H series extruder offers stable operation, high throughput, and optimized energy use. Its smart control system enables producers to fine-tune parameters for different raw materials and formulations, helping reduce production costs while boosting efficiency.

Conclusion:

From formulation flexibility to reliable performance, the FAMSUN Twin-Screw Aqua Extruder empowers aquafeed producers with advanced processing capabilities. As a top-tier food extruder solution, it reflects FAMSUN’s commitment to quality, innovation, and sustainability in aquatic nutrition.